About us

Factory

After years of development, BMC had more pieces (sets) of all kinds of production and testing equipment such as NC cutting machines, NC veneer reeling machines, NC drilling machines, NC lathes, NC wire cutting machines, automatic welding machines, automatic plate reeling machines, imported tube plate welding machines, sand blasting machines, universal material testing machines, impact testing machines and flaw-detecting machines and set up “Quality Testing Center”, by which BMC can carry out scientific research such as physical and chemical testing, nondestructive testing, welding experiment and oil & fat experiment and “a Pressure Pipeline Design Room”to provide comprehensive technical support for oil & fat engineering.

1. Production Facilities:

Electrical workshop

Secondary welding material storage

Household store

Finished product warehouse

Gas cutting machine

Automatic welding machine

CNC drilling machine

Wire cutting machine with CNC

Hydraulic press

ERP operation terminal

Library of records

Library of records

lathe

Plasma cutting

Plasma welding machine

Automatic welding machine for pipe flanges

Automatic welding machine for circular fillet welds

Laser cutting

Sandblasting shop

Wire drawing machine with flat grinding and water

Test bench

Tubularresist machine with CNC

CNC drilling machine

Hydraulic bending machine for sheet metal

Emergency room

Equipment in production

Equipment in production

Equipment in production

Equipment in production

Automatic machine for welding longitudinal rings

2. Inspection and Detection Facilities:

Universal material testing machine

Equipment for non-destructive testing

Radiation dose equivalent power meter

Laser marking machine

Tвердомер by Liбу

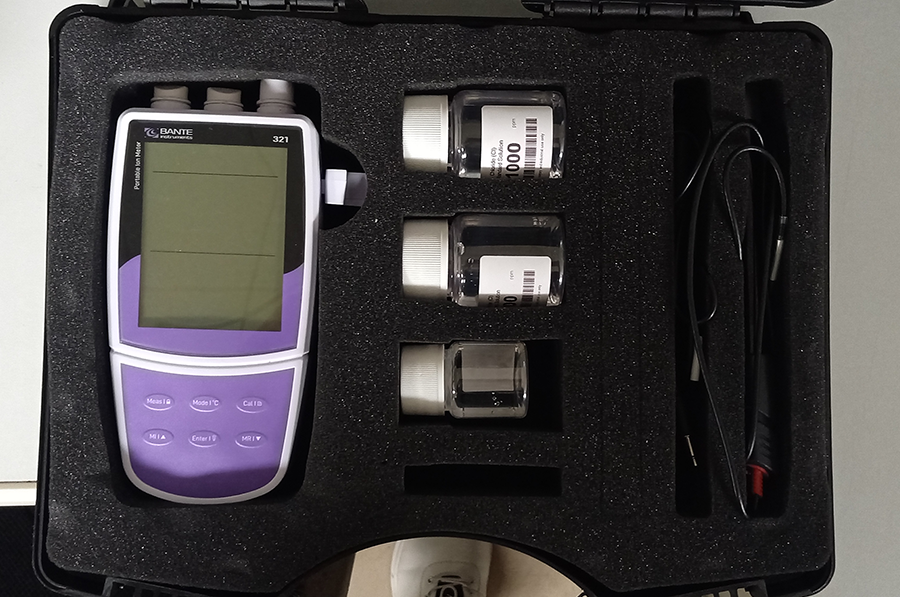

Chloride ion detector

Energy-dispersive X-ray fluorescence spectrometer

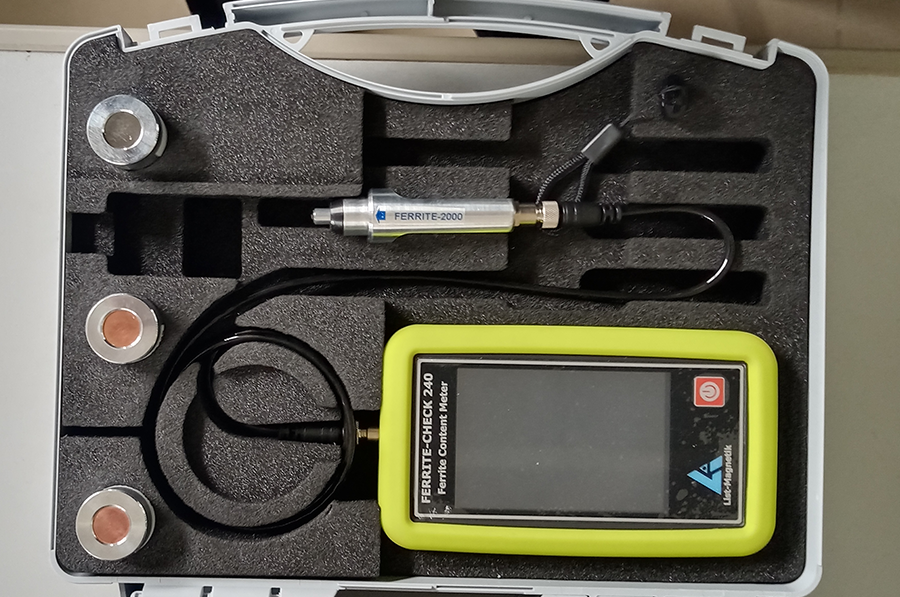

Ferrite meter